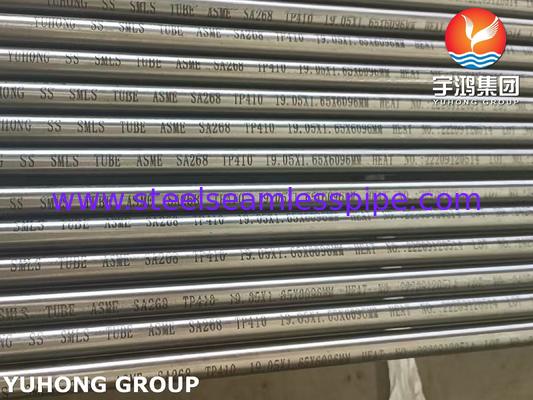

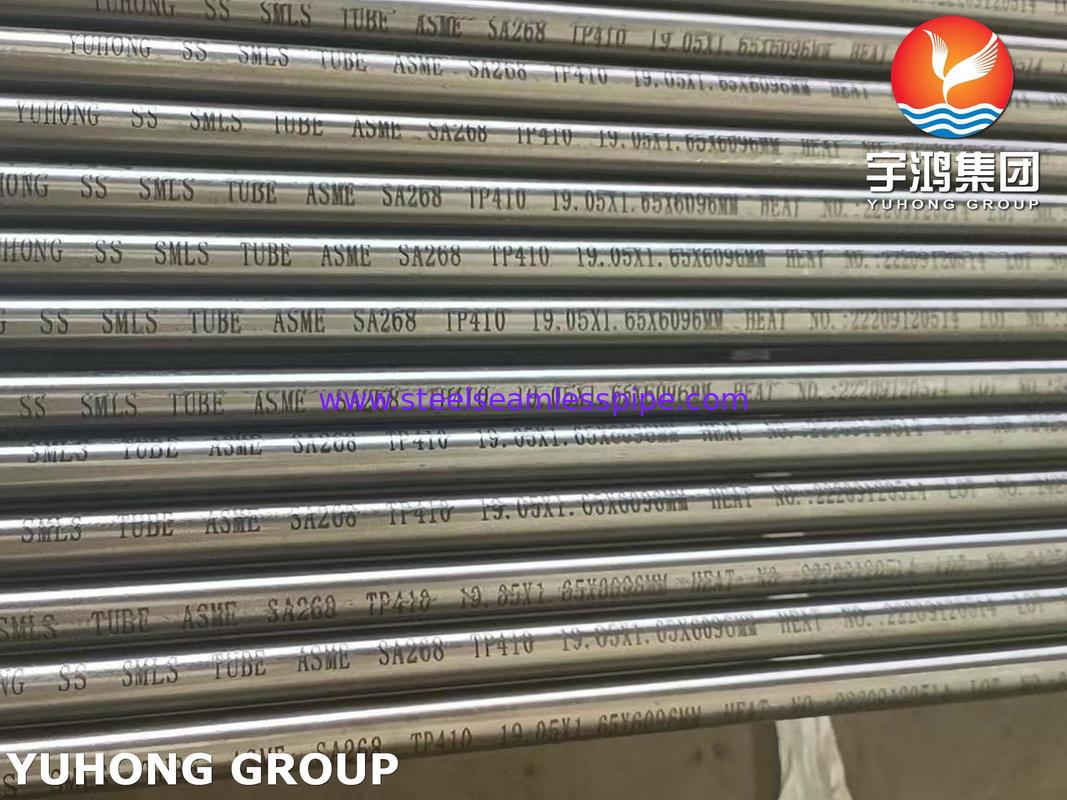

ASME SA268 TP410 縫い目のないステンレス鋼管

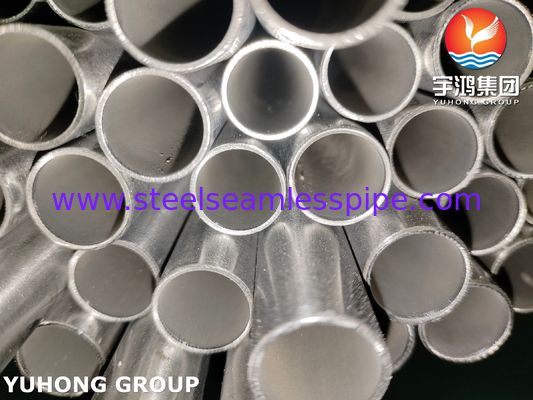

ASME SA268 TP410シームレスステンレス鋼管は,中程度の耐腐食性,高強度,硬さで知られる広く使用されるマルテンシート級です.シームレスプロセスで製造されます.圧縮されたアプリケーションの構造的整合性を保証しますこのグレードは,通常,熱処理条件で供給される,例えば,熱焼かしたり,消し,冷却したりして,望ましい機械的性質を達成するために,蒸気システムを含む様々な産業用用途に適している油井管,熱交換器,機械部品

TP410は,およそ11.5%のクロムを含む基本マルテンシト性クロム不酸化鋼で,温かい環境で耐腐蝕性を提供します.304または316などのオーステニトグレードとは異なり,磁性があり,熱処理によって強化できる熱処理条件によって決定される.

化学成分 (%)

| エレメント |

C について |

ミニ |

そうだ |

P |

S |

C.C. |

Ni (選択可能) |

| 範囲 |

≤0.15 |

≤ 100 |

≤ 100 |

≤0.040 |

≤0.030 |

11.5-13 だった5 |

≤0.60 |

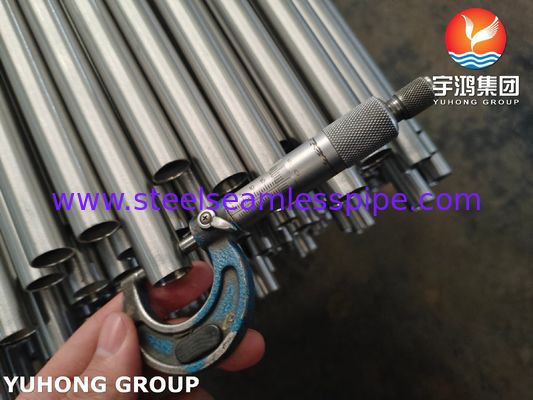

メカニカルプロパティ

| 張力強度 |

利回り強さ (0.2%オフセット) |

伸縮 (% 2インチ) |

硬さ (ブリーネル) |

| ≥415 MPa |

≥205 MPa |

≥ 25% |

≤ 217 HB |

注: 消し,加熱されたTP410は,より高い強度と硬度値を達成することができる.

一般的に参照される同等の材料

| ASTM/ASME |

UNS |

EN について |

EN (指定) |

JIS |

DIN |

| TP410 |

S41000 |

1.4006 |

X12Cr13 |

SUS 410 |

X10Cr13 |

比較:TP304 VS TP410 VS TP316

| グレード |

主要 な 特徴 |

主要アプリケーションガイド |

| TP304 |

優れた形容性,一般的な腐食耐性 |

一般的な腐食性サービス (例えば食品,飲料,化学品) の最も一般的な選択です. |

| TP410 |

高強度と硬さ,磁性,中程度の腐食耐性 |

温かい環境 (蒸気,バルブ,食器など) で機械的特性 (耐磨性,耐久性) により選択される. |

| TP316 |

特に塩化物や酸に耐性がある |

攻撃的な環境 (海水,化学加工,パルプ&紙など) のためのプレミアム選択です |

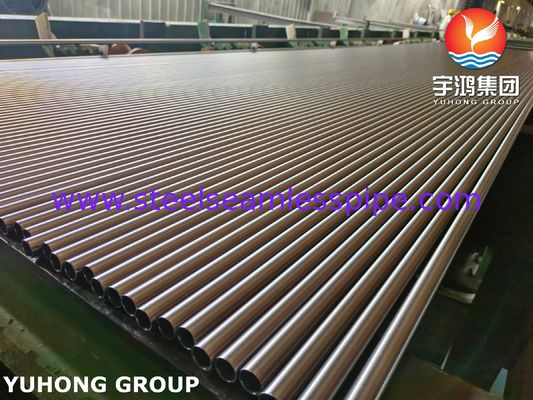

ASME SA268 TP410 ステンレス鋼管の適用

1電力発電:低圧蒸気管,給水給湯器,蒸気凝縮液管は 温かい状態で

2石油・ガス甘い (酸性でない) 生産環境のための井戸管と流通線

3熱交換器:シェルとチューブ熱交換器は 淡水,油,有機化学物質などのメディアです

4機械部品:耐磨性が必要な液圧シリンダー管,ベアリングスリーブ,ブッシング,マンドル

5自動車:燃料注入ラインと排気システムの特定の部品

6一般工学: 高圧加工管と機械の構造部品

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!