1. SB338 GR.2 R50400 Titanium Steel Tube Mechanical and Physical Properties

GR.2 titanium offers a unique blend of mechanical and physical properties, making it suitable for critical applications.

- Mechanical Properties:

- Tensile Strength: ≥345 MPa .

- Yield Strength: ≥275 MPa.

- Elongation: ≥20% (indicating good ductility).

- Comparison with Stainless Steel: Higher strength-to-weight ratio (density ~4.51 g/cm³, ≈60% of steel).

Physical Properties:

- Density: 4.51 g/cm³.

- Crystal Structure: α-titanium (hexagonal close-packed).

- Magnetic Properties: Non-magnetic.

- Thermal Conductivity: ~17 W/(m·K) (lower than copper alloys but compensated by thin-walled designs).

2. SB338 GR.2 R50400 Titanium Steel Tube Corrosion Resistance and Performance

GR.2 titanium is renowned for its exceptional corrosion resistance, particularly in aggressive environments.

Key Corrosion Resistance Properties:

- Seawater and Marine Environments: Corrosion rate <0.0005 mm/year, even after 30 years of immersion.

- Oxidizing Media: Resists nitric acid (65% boiling, corrosion rate <0.005 mm/year), wet chlorine, and hypochlorite solutions.

- Weak Reducing Acids and Alkalis: Performs well in alkaline environments and some organic acids.

- Immunity to Localized Corrosion: Highly resistant to pitting and stress corrosion cracking (SCC) in chlorides.

- Mechanism: Forms a stable, adherent oxide layer (TiO₂) that self-repairs if damaged, providing passive protection.

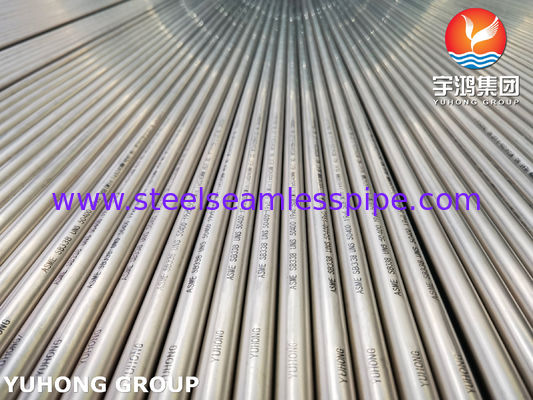

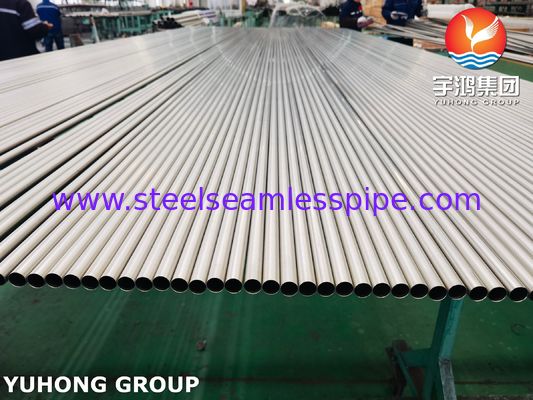

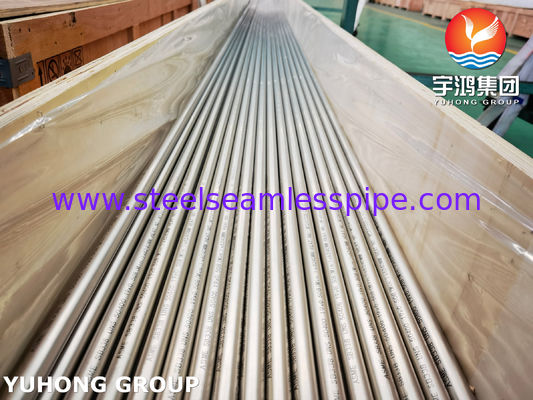

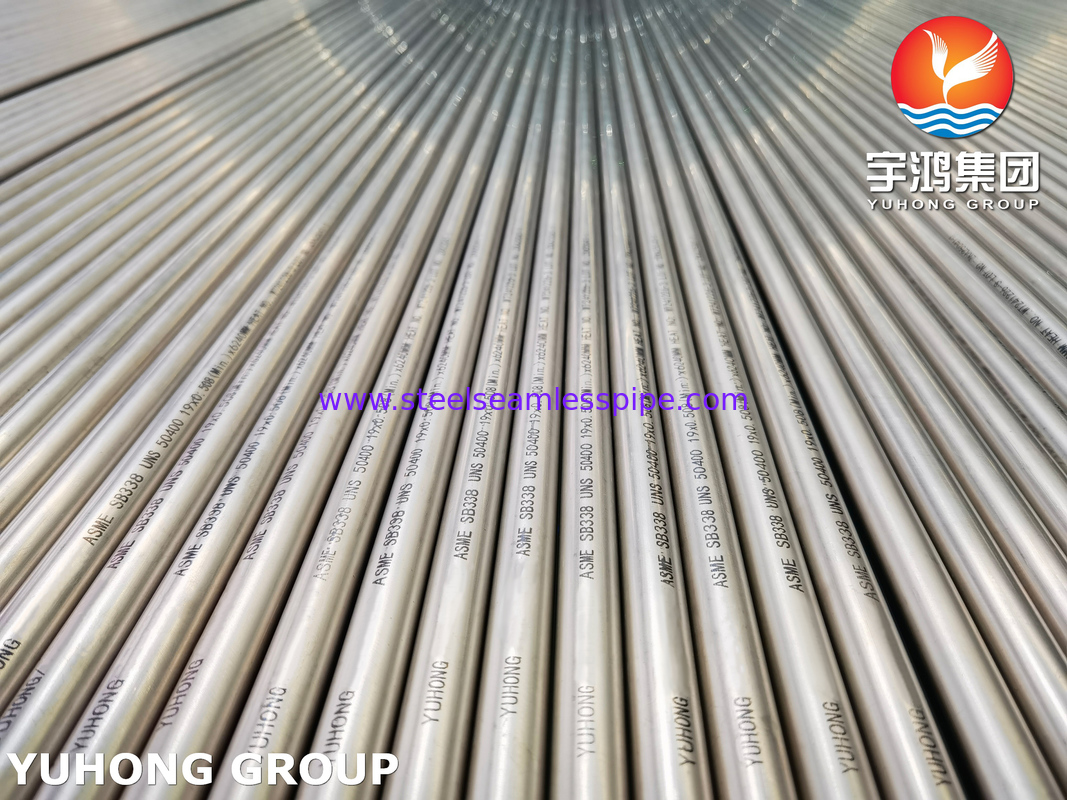

3. SB338 GR.2 R50400 Titanium Steel Tube Manufacturing and Fabrication

Production Process:

- Seamless tubes are manufactured via extrusion, piercing, and cold rolling.

- Welded tubes are made from rolled sheets or strips welded using TIG or plasma methods.

Fabrication Characteristics:

- Formability: Good ductility and cold workability (n≈0.35 hardening index).

- Weldability: Excellent; commonly welded using ERTi-2 filler via TIG/MIG without preheating or post-weld heat treatment.

- Machining: Requires low speeds, high feed rates, and carbide tools with emulsion cooling for best surface finish (Ra ≤0.4 μm).

4. SB338 GR.2 R50400 Titanium Steel Tube Applications in Industry

GR.2 titanium tubes are widely used in industries where corrosion resistance, lightweight, and reliability are critical.

- Heat Exchangers and Condensers: Power Plants: Nuclear and fossil fuel condensers. Chemical Processing: Heat exchangers for corrosive media (e.g., acids, chlorides).

- Sea Water Desalination: Evaporators and Condensers: Preferred over copper alloys due to superior resistance to erosion, corrosion, and biofouling. Thin-walled tubes (e.g., 0.5 mm) reduce weight and cost.

- Chemical and Petrochemical Industry:Reactors, Pipes, and Vessels: For handling nitric acid, hypochlorite, and organic chlorides.

- Marine and Offshore: Shipbuilding: Heat exchangers, piping systems, and structural components. Deep-Sea Equipment: Subsea connectors and risers.

- Aerospace: Hydraulic Systems and Airframes: Lightweight components requiring strength and corrosion resistance.

- Medical: Implants and Surgical Instruments: Biocompatibility and resistance to sterilization agents.

5. SB338 GR.2 R50400 Titanium Steel Tube Advantages Over Competing Materials

Compared to Copper Alloys:

- Longer Life: Immune to erosion-corrosion and biofouling in seawater.

- Weight Savings: Density ~4.51 g/cm³ vs. ~8.9 g/cm³ for copper alloys; thin-walled designs reduce weight by up to 75%.

- Thermal Performance: Lower thermal conductivity compensated by thin walls and fouling resistance.

Compared to Stainless Steel and Nickel Alloys:

- Cost-Effectiveness: Lower life-cycle cost and ~50% cheaper than nickel alloys in many applications.

- Superior Corrosion Resistance: Outperforms stainless steels in chlorides and oxidizing acids.

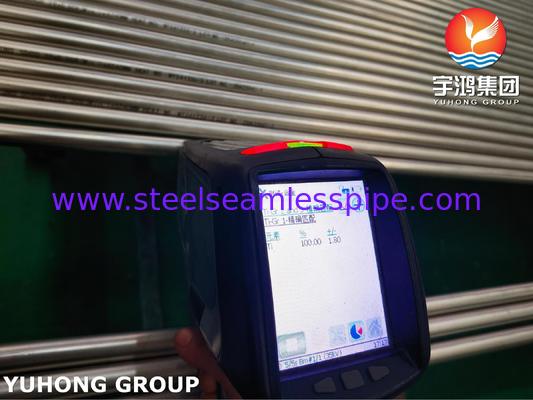

6. SB338 GR.2 R50400 Titanium Steel Tube Quality Assurance and Testing

Testing Standards:

- Chemical Analysis: Per ASTM E1409.

- Mechanical Testing: Tensile, flattening, flaring, and hardness tests per ASTM B338.

- Non-Destructive Testing: Eddy current, ultrasonic, or hydrostatic tests.

Certification: Suppliers provide EN 10204 3.1 certification and ISO 9001 quality management.

Conclusion

The ASME SB338 GR.2 R50400 titanium seamless tube is a highly reliable material for critical applications in corrosive environments. Its excellent corrosion resistance, mechanical properties, and compliance with international standards make it a preferred choice in industries such as chemical processing, power generation, marine, and aerospace. When selecting this material, consider dimensional tolerances, fabrication requirements, and total life-cycle cost to maximize project success. For detailed specifications, always refer to the latest ASME SB338 standard.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!