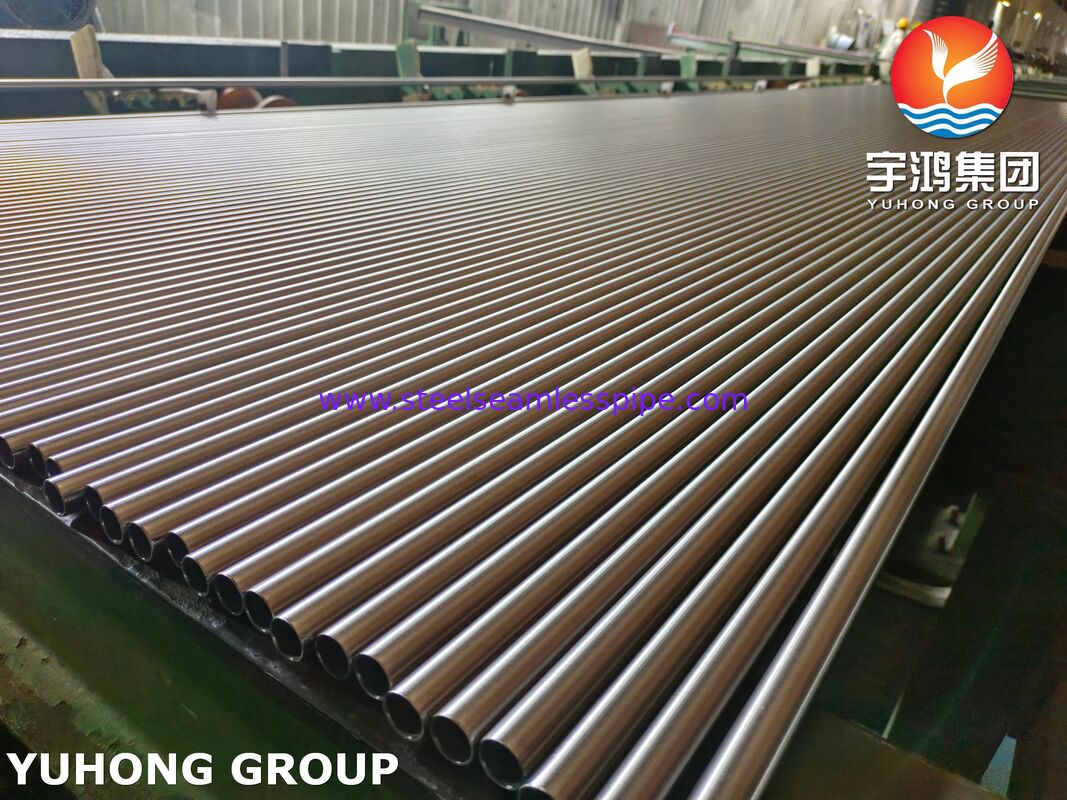

- YUHONG brand goods have been already exported to more than 85 countries With more than 35 years' experience, because of strict quality control policy, excellent sales service, delivery on time. YUHONG won more and more new clients and got more and more repeat orders from old clients, in YUHONG People's mind: Quality is First Important!

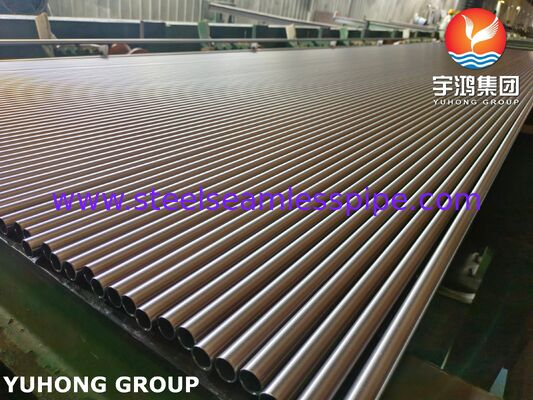

ASME SA268 TP410 (UNS S41000) Ferritic and Martensitic Seamless Stainless Steel Tube

ASTM A268 is standard specification for Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service, the grades contain TP410, TP405, TP420, TP430, TP430Ti, TP403, TP409, TP444, TP439 and TP446.

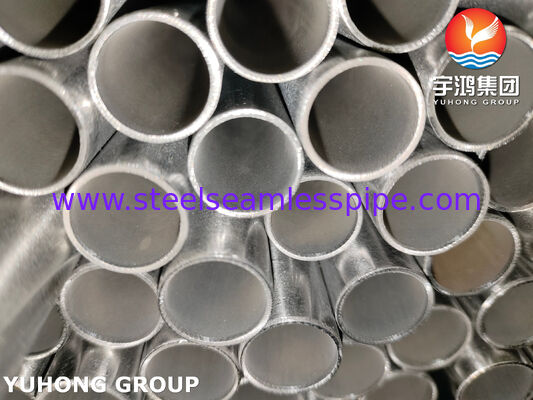

This specification covers a number of grades of nominal-wall-thickness, stainless steel tubing for general corrosion-resisting and high-temperature service. Most of these grades are commonly known as the "straight-chromium" types and are characterized by being ferromagnetic. Two of these grades, TP410 and UNS S 41500 (Table 1), are amenable to hardening by heat treatment, and the high-chromium, ferritic alloys are sensitive to notch-brittleness on slow cooling to ordinary temperatures. These features should be recognized in the use of these materials.

ASME SA268 TP410 (UNS S41000) is a heat-treatable ferritic and martensitic seamless stainless steel tube, primarily alloyed with chromium (approx. 12.5%) and containing no nickel. In the annealed condition, it offers moderate corrosion resistance and good formability, and can be strengthened to higher levels of hardness, strength, and wear resistance through quenching and tempering. Being magnetic and exhibiting better resistance to chloride stress corrosion cracking than austenitic stainless steels, it is commonly used in applications requiring a balance of corrosion resistance and mechanical performance, such as heat exchanger tubes, boiler tubing, instrumentation pipes in petrochemical systems, and automotive exhaust components.

| ASTM |

UNS |

WERKSTOFF NR. |

GB |

EN |

JIS |

| A268 |

S41000 |

1.4006 |

06Cr13 |

X6Cr13 |

SUS 410 |

1.Chemical & Mechanical Properties

| ASME SA268 TP410 Chemical Composition (%) |

| C |

Mn

|

P |

S |

Si

|

Cr |

| ≤0.15% |

≤1.00% |

≤0.04% |

≤0.03% |

≤1.00% |

11.5%~13.5% |

Mechanical Properties

|

Tensile Strength

|

Yield Strength |

Elongation |

Brinell Hardness |

Rockwell Hardness

|

| ≥ 415MPa |

≥ 205MPa |

≥ 20% |

≤ 207 |

≤ 95 |

2. Key Adventages

- Excellent Cost-Effectiveness

Saves Material Cost: As a nickel-free chromium stainless steel, its price is significantly lower than austenitic grades like 304 or 316, substantially reducing project costs while meeting performance requirements.

Reduces Fabrication Cost: Exhibits good machinability, tube bending, and weldability (requires preheating and post-weld heat treatment) in the annealed condition, facilitating downstream manufacturing.

Customizable Properties: This is the most fundamental distinction from purely ferritic stainless steels (e.g., 409/430). Its final strength, hardness, and toughness profile can be flexibly adjusted through "quenching and tempering" heat treatment to meet diverse needs, from high-toughness structural parts to high-hardness wear-resistant components.

- Superior Resistance to Stress Corrosion Cracking

Solves Specific Environmental Challenges: In chloride-containing, warm environments, its resistance to stress corrosion cracking is significantly better than common austenitic stainless steels (e.g., 304). This makes it especially suitable for critical equipment like heat exchangers and condensers prone to this failure mode.

- Good Overall Mechanical Properties

Balance of Strength and Toughness: After heat treatment, it can achieve high strength while maintaining sufficient toughness, offering better overall mechanical performance than carbon steel.

3. Key Applications

- Heat Exchangers & Condensers

-

Boiler Tubes & Superheater Tubes

-

Oil & Gas Industry

-

Automotive Exhaust System Components

-

General Engineering Structures

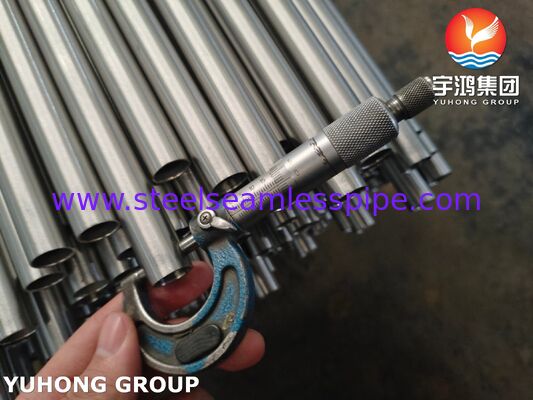

ASTM A268 TP410 (1.4006, UNS S41000, X12Cr13) Martensitic Steel Seamless Tube Test Scope:

- Tension test

- Flaring test (for seamless tubes)

- Flange test (for welded tubes)

- Hardness test

- Reverse flattening test

- Intergranular corrosion test

- Hydrostatic or nondestructive electric test

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!